Have a virtual trip in our motors factory or download the presentation: you will see step by step how we create and customize our stepper and BLDC motors!

HIGH PERFORMANCE, HIGH EFFICIENCY AND DURABLE MOTORS: THE PROCESSING STEPS

HOW WE PRODUCE OUR MOTORS

|

Internal design allows us to create highly customized motors,

perfectly in line with customers needs

|

PRODUCTION PROCESS THE PHASES

|

Endbells machining

After aluminium die-casting, the flanges are ground and machined to ensure the precision and the customizations required by our customers

| |

Rotors grinding

The rotors are first assembled with automatic presses, then are resinated to ensure greater compactness and rust resistance and finally are ground with automatic grinding machines and with micrometric precision | .png) |

Stators holing

The stators are lapped and 100% inspected to ensure an air gap of a few microns | |

Coils winding

Each motor, whether BLDC or stepper, is wrapped with automatic winders able to guarantee repeatability and stability in series production |

|

Mechanical assembling

Skilled workers assemble our motors carefully, welding the windings to the motor cables with specifically designed PCB and ensuring optimal fixing between axles and bearings |

|

|

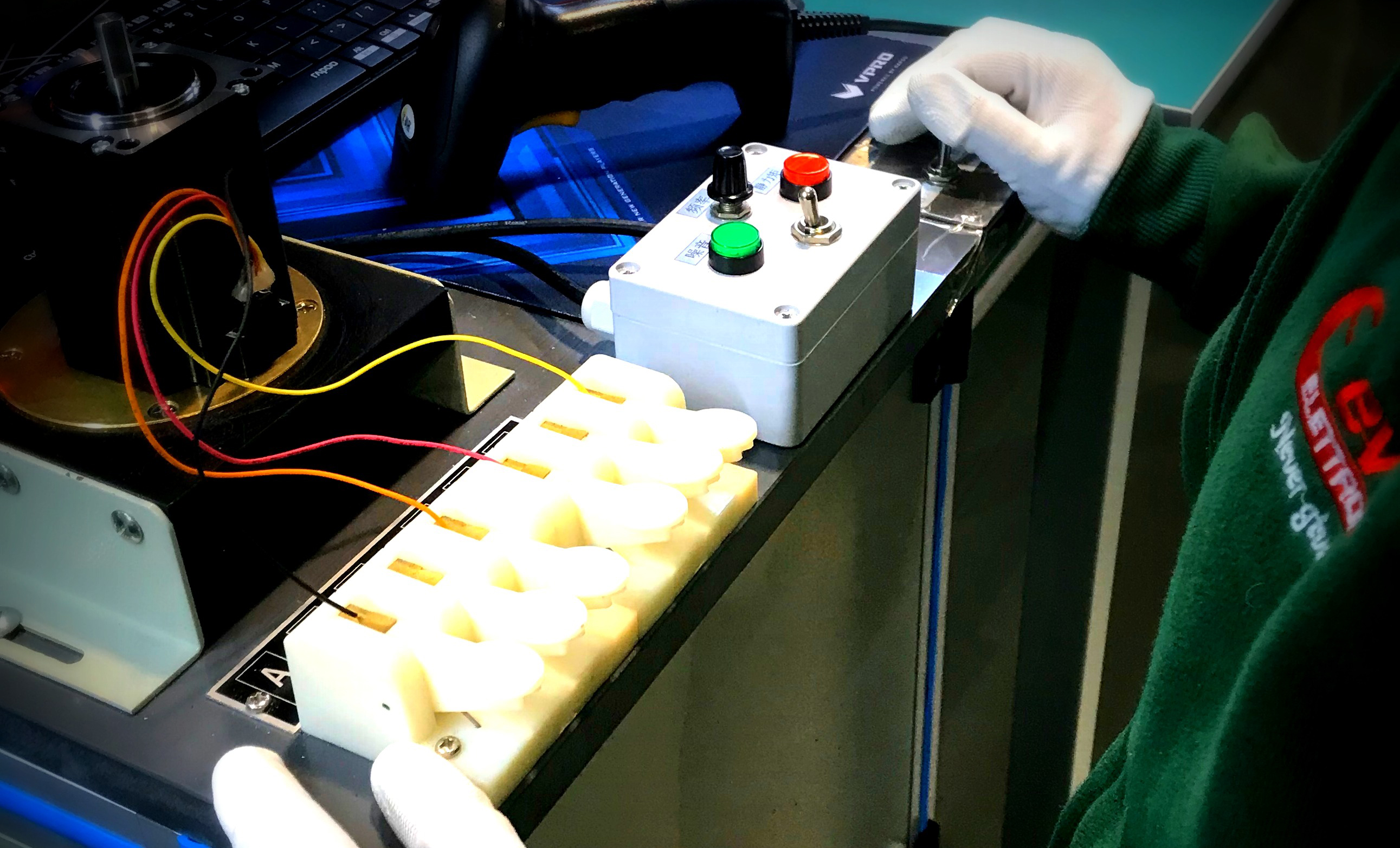

Magnetization

Each motor, once assembled, is magnetized ensuring high torque performance |

|

Testing phase

Our motors are 100% inspected..

Motors testing phase is carried out by automatic test machines. Every data is saved in a database and traceability is guaranteed thanks to the Serial ID printed on each motor. |

|

"Quality is not random;

it is always the result

of intelligent effort.""

|